Achieve next-level performance, energy efficiency, and purity with advanced Compressed Air & Gas Solutions for EV Battery Production. These systems are engineered to meet the demanding requirements of every phase in electric vehicle battery manufacturing—from mixing and coating to drying, leak testing, and final assembly.

Sustainable Manufacturing with Compressed Air & Gas Solutions for EV Battery Production

Clean and efficient systems are essential for reducing emissions and ensuring safe, high-quality battery assembly. Our Compressed Air & Gas Solutions for EV Battery Production help automotive OEMs and battery suppliers meet sustainability goals without sacrificing precision.

Full Process Coverage with Compressed Air & Gas Solutions for EV Battery Production

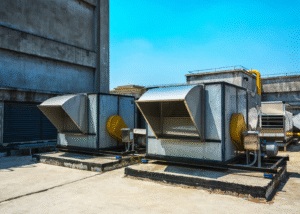

From air compressors and nitrogen generators to dryers, filters, and vacuum blowers, our Compressed Air & Gas Solutions for EV Battery Production cover all critical applications in the battery value chain. You get a complete, integrated system from a single provider, designed for peak efficiency and reliability.

Cost-Efficient Performance

Every component within our Compressed Air & Gas Solutions for EV Battery Production is selected for low total cost of ownership. With smart controls, leak reduction, and energy recovery features, manufacturers can reduce both operating expenses and CO₂ output.

Why Clean Air and Gas Matter

The precision and safety of electric vehicle battery manufacturing rely on dependable Compressed Air & Gas Solutions for EV Battery Production. Whether it’s electrode coating, electrolyte filling, or vacuum handling, these systems ensure consistent pressure and zero contamination.

Smart Control for High-Volume Battery Plants

Large-scale production demands scalable infrastructure. Our centralized controllers ensure Compressed Air & Gas Solutions for EV Battery Production operate efficiently by orchestrating multiple compressors and gas generators in harmony—delivering exactly what your plant needs, when it’s needed.

Key Applications Powered by Compressed Air & Gas Solutions for EV Battery Production

-

Electrode Mixing and Coating

Stable airflow for slurry blending and defect-free coating. -

Cell Assembly and Electrolyte Filling

Controlled environments made possible with dry, filtered air. -

Leak Testing and Vacuum Processes

Vacuum pumps integrated into our Compressed Air & Gas Solutions for EV Battery Production ensure precision and repeatability. -

Component Drying and Purging

Dryers and nitrogen systems maintain strict humidity control. -

Safety Valve Testing and Nitrogen Filling

Custom nitrogen solutions integrated seamlessly with your air infrastructure.

Each application is supported by customized Compressed Air & Gas Solutions for EV Battery Production to improve uptime, consistency, and compliance.

Purity & Compliance Guaranteed

Our Compressed Air & Gas Solutions for EV Battery Production ensure ISO 8573-1 Class 0 oil-free air, along with on-site nitrogen purity up to 99.999%. These systems help eliminate the risk of product defects and meet global regulatory standards.

Global Support for Compressed Air & Gas Solutions for EV Battery Production

We offer international installation, remote monitoring, performance audits, and 24/7 maintenance. With our trusted service ecosystem, you’ll always get expert support for your Compressed Air & Gas Solutions for EV Battery Production.

Download Our eBook on EV Battery Manufacturing

Learn how to design and scale a full plant-wide system with our dedicated guide on Compressed Air & Gas Solutions for EV Battery Production. Discover best practices, product configurations, and real-world case studies.

Benefits of Our Compressed Air & Gas Solutions for EV Battery Production

-

Energy savings of up to 50% with VSD-enabled systems

-

Oil-free air prevents contamination in sensitive stages

-

Scalable modular design adapts to changing demand

-

Integrated air & gas systems simplify operations and reduce maintenance

-

Complete lifecycle support for continuous reliability

Our Compressed Air & Gas Solutions for EV Battery Production are the backbone of reliable and efficient electric vehicle battery manufacturing.

Industry Success with Compressed Air & Gas Solutions for EV Battery Production

-

A global EV manufacturer cut energy use by 45% after upgrading to our optimized Compressed Air & Gas Solutions for EV Battery Production.

-

A battery gigafactory improved drying process uptime by 60% using integrated nitrogen and air systems.

-

Multiple Tier 1 suppliers report fewer leak test failures due to stable vacuum support from our solutions.

These success stories reflect how Compressed Air & Gas Solutions for EV Battery Production directly enhance performance across multiple touchpoints.

Compliance Meets Innovation

Our systems meet all international manufacturing standards—ISO 9001, ISO 14001, ISO 1217—while supporting clean energy production goals. All Compressed Air & Gas Solutions for EV Battery Production are built with sustainability and future scalability in mind.

Conclusion

For manufacturers looking to scale, optimize, and future-proof their electric vehicle production, choosing the right infrastructure matters. Our Compressed Air & Gas Solutions for EV Battery Production provide:

-

Unmatched air purity and system uptime

-

Optimized performance for critical battery processes

-

Lower energy costs and environmental impact

-

End-to-end system integration and expert service

-

Ready-to-scale architecture for gigafactory setups

Let us help you build a smarter, cleaner, and more reliable battery manufacturing environment with world-class Compressed Air & Gas Solutions for EV Battery Production.