ASG Energy provides a comprehensive range of oil-free air blowers, specifically engineered for applications requiring compressed air at pressures between 0.3 and 1.5 bar(g).

Complete Air Blower Packages for Easy Installation

Our plug-and-play solutions simplify the installation process, eliminating the need to purchase additional components. With ASG Energy, your blower units are ready for operation as soon as they are installed.

Maximizing Energy Savings with VSD Technology

Our Variable Speed Drive (VSD) technology ensures that your units use only the energy necessary, effectively decreasing energy consumption and reducing environmental impact.

Simplifying Supervision and Maintenance

To further enhance efficiency and ease of use, we offer various ways to monitor and control your blower systems, improving both supervision and maintenance tasks.

Why Oil-Free Blower Technologies?

Blowers serve a variety of processes in industries such as cement, food & beverage, and wastewater treatment. Typical low-pressure applications include:

Aeration

Fermentation

Pneumatic conveying

Heating or cooling of materials

Selecting the correct blower technology can result in significant energy savings. By properly sizing the blower, you can achieve a more energy-efficient process. For applications requiring low-pressure compressed air between 0.3 and 1.5 bar(g) (4 psig to 22 psig), replacing an air compressor with an air blower can reduce energy waste. For every 1 bar(g) (14 psig) that air is compressed above the demand, 7% of energy is wasted.

ASG Energy offers various blower technologies, including:

Positive displacement technologies (e.g., screw and lobe blowers)

Centrifugal technologies (e.g., high-speed turbo blowers and multistage blowers)

Our oil-free air blower technologies are engineered to provide high-quality air and maximum uptime, ensuring the quality of your end product.

Choosing the Right Blower for Your Production Process

When selecting the right air blower, it’s essential to consider factors like airflow, pressure needs, and cost. The initial investment cost and return on investment (ROI) also play a critical role in the decision-making process.

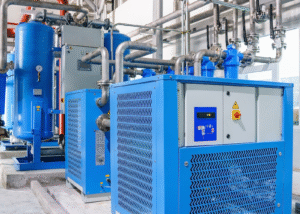

Energy Efficiency vs. Initial Investment

Up to 80% of a blower’s lifecycle cost is consumed by energy usage. To minimize operating costs, ASG Energy provides energy-efficient solutions, such as:

ZS Rotary Screw Blowers

ZB VSD⁺ Turbo Blowers

These oil-free screw and turbo blowers are Class 0 certified, offering low operational costs and energy savings. Optimize your compressed air installation with our central controllers.

For businesses focusing on initial investment costs, we also offer simple and robust solutions like:

ZL Lobe Blowers

ZM Multistage Centrifugal Blowers

These are well-suited for harsh environments and high-altitude operations.

Product Range:

ZS (VSD+) Oil-Free Rotary Screw Blowers

Capacity (FAD): 64 l/s – 2,528 l/s

Working Pressure: 0.3 bar(e) – 1.5 bar(e)

Motor Power: 18 kW – 355 kW

ZL (VSD) Oil-Free Lobe Blowers

Capacity (FAD): 5 l/s – 2,767 l/s

Working Pressure: 0.3 bar(e) – 1 bar(e)

Motor Power: 0.55 kW – 315 kW

ZM Oil-Free Multistage Centrifugal Blowers

Capacity (FAD): 47 l/s – 18,880 l/s

Working Pressure: 0.14 bar(e) – 1.7 bar(e)

Motor Power: 4 kW – 2,600 kW

ZB VSD+ Oil-Free Centrifugal Air Blowers

Capacity (FAD): 556 l/s – 5,556 l/s

Working Pressure: 0.3 bar(e) – 1.4 bar(e)

Motor Power: 100 kW – 400 kW